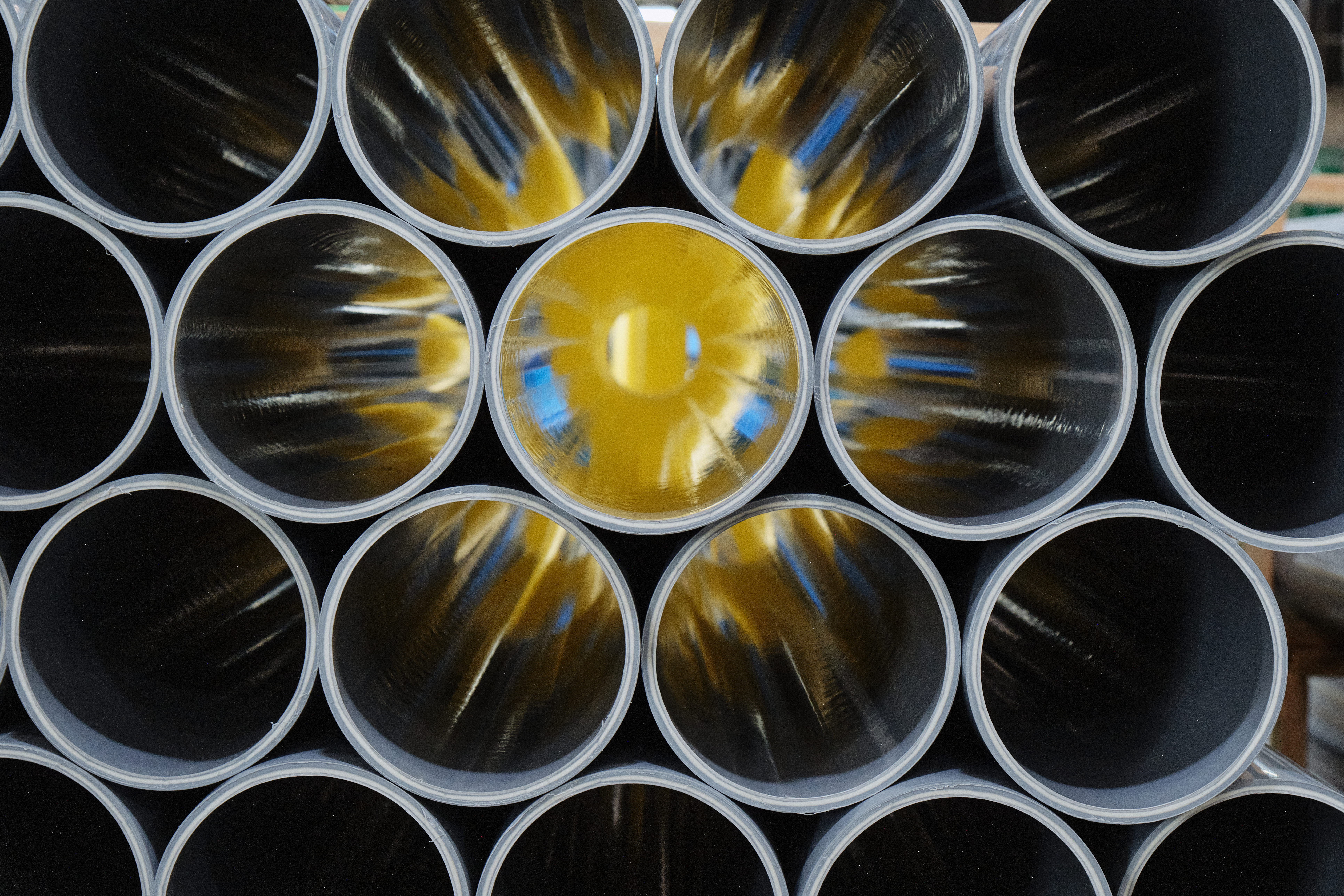

New Test Results Released Confirming JM Eagle’s PVC Pipe Meets Industry Standards

Favorable Evidence Follows Proof of Fraud, Kick-Back Scheme Perpetrated by Former Employee Hendrix.

Los Angeles- February 24, 2010 –JM Eagle today released the results of new tests conducted by one of North America’s leading testing and engineering firms, Jana Laboratories, confirming that JM Eagle’s PVC pressure pipe meets the requirements for long term strength. The test results are a sharp blow against the unsubstantiated allegations leveled against JM Eagle’s PVC pressure pipe by former JM Eagle employee John Hendrix, who claimed that JM Eagle’s pipe does not meet these requirements. As JM Eagle announced last week, Hendrix had been terminated by JM Eagle because of his involvement in a kickback scheme. This scheme has been proven by sworn testimony by the customer who “blew the whistle” and reported Hendrix’s illegal offer to obtain a better recovery for the customer in a claim in exchange for a cash kickback to be mailed to his “home address,” which was heard by one or more other witnesses. The sworn affidavit testifying to this illegal conduct by Hendrix has been sent to criminal authorities.

The U.S. Department of Justice recently completed an exhaustive three-and-a-half year investigation into Hendrix’s allegations, during which it requested JM Eagle to segregate and send to it certain pipe samples that had been produced prior to JM Eagle’s knowledge of the qui tam lawsuit in 2006. It was revealed last week that, following this investigation, the U.S. Government declined to intervene in the case. The State Attorney Generals of California and Florida have likewise declined to be a party to the suit.

The testing completed by Jana Laboratories was on two sets of pipe. One set was taken from the same lot of pipe that was submitted to the federal government for testing during its investigation. This pipe was manufactured in June 2006, prior to JM Eagle having knowledge of the qui tam lawsuit. The second set was taken from JM Eagle inventory in August 2009.The tests that were conducted were 2000-hour tests to determine the pipes’ ability to withstand long-term pressure, known as their “hydrostatic design basis.” Each set met the 4000 psi requirement.

“Every one of JM Eagle’s more than 1,600 employees across the United States is committed to producing high quality products,” said JM Eagle President and CEO Walter Wang. “We are pleased to reveal clear evidence of our products’ long-term strength and reliability.”

Though four states and several municipalities in California have apparently chosen to intervene in the case, none of these entities have ever registered a complaint with JM Eagle regarding its pipes. Indeed, the Attorney General’s office in Delaware publicly stated that Delaware had no known failure of pipes. The intervening entities also did not engage in any sustained discussions of the facts or merits of the allegations with JM Eagle, as did the federal government and the State of California, which each declined to intervene.

“We are confident that the more the proper authorities in Virginia, Tennessee, Nevada and Delaware, as well as the handful of California cities who are today still a party to the litigation, look closely at John Hendrix, they will not like what they see,” said Wang. “Once these entities look at the facts of the case, and the evidence we have, they will quickly determine that this is a dishonest individual who not only doesn’t deserve their trust, but an individual who wished to defraud the government as well as

JM Eagle.”

In addition to the special testing announced today, which is above and beyond any requirements under industry standards, the Los Angeles-based manufacturer’s PVC pipe products are certified by the nation’s foremost independent agencies including Underwriters Laboratories (UL) and NSF International. JM Eagle’s plants are subjected to unannounced visits and random testing by these agencies and others to ensure the quality of the products produced. Since 2000, JM Eagle has produced more than 11 billion feet of pipe and the number of gross product claims is less than tenth of a percent, far below the industry average.